Machine Tending

What is

Robotic machine tending refers to the use of robots to automate the loading and unloading of machine tools in a manufacturing environment. This type of automation is prevalent in manufacturing industries, where it enhances efficiency, reduces machine downtime, and increases workplace safety.

Common application

Machine Tools

- Lathe

- Milling machine

- Machining center

Injection Molding

Handling plastic components

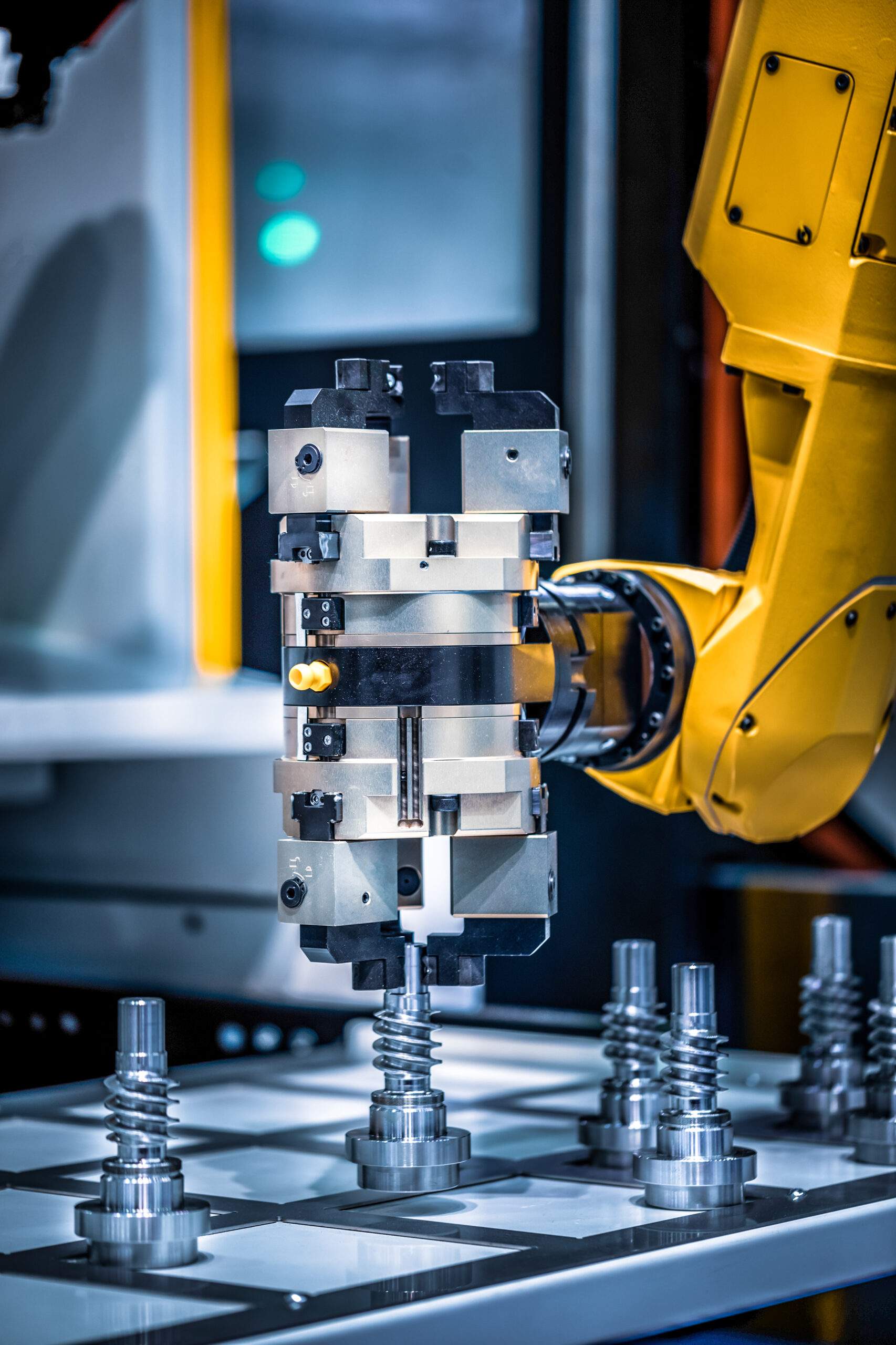

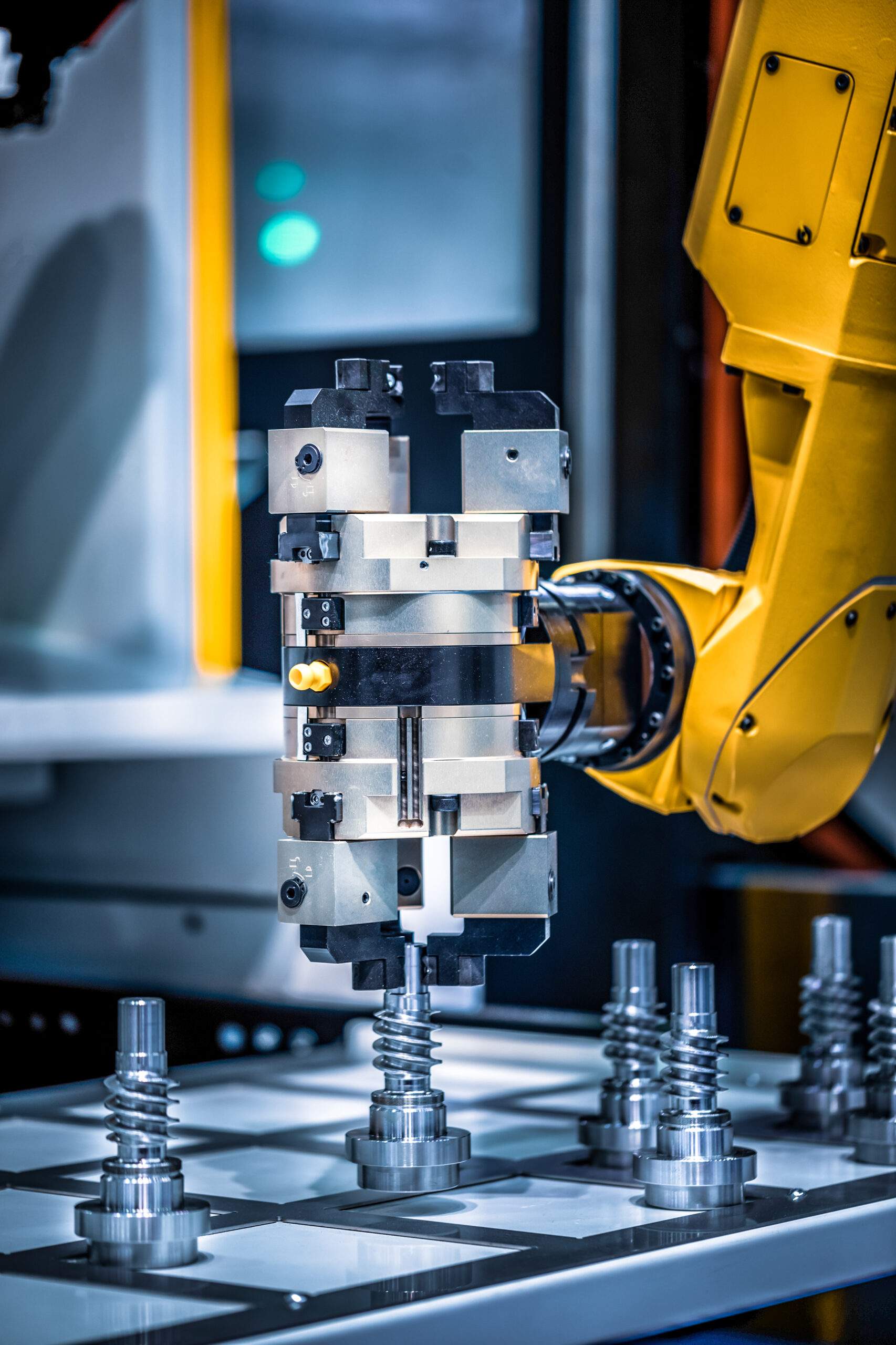

CNC Machining Process

Loading and unloading raw and finished materials

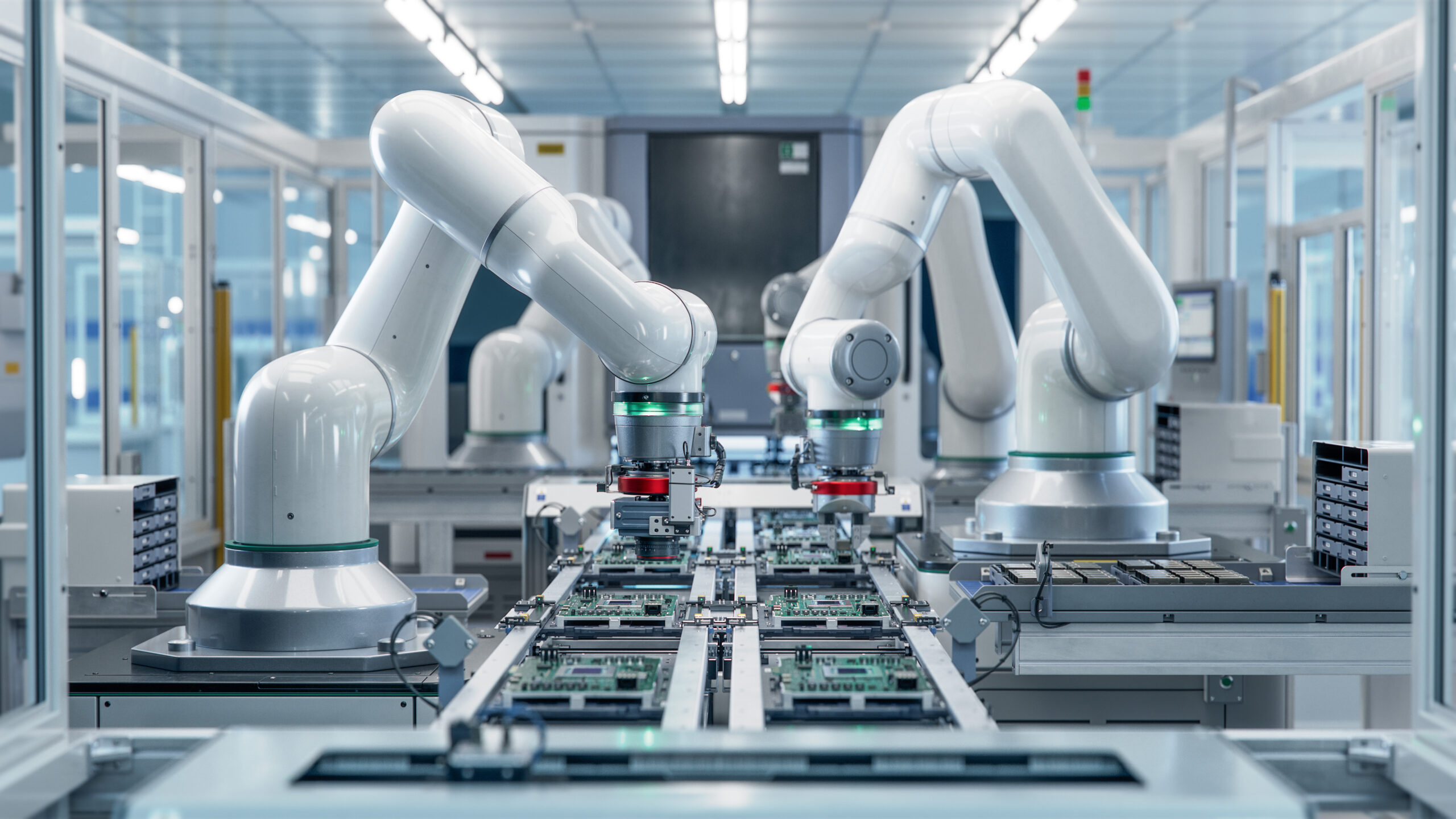

Assembly and Inspection

Automated assembly operations and quality control

Advantages of Robotic Tending

Increased Productivity

Robots can operate 24/7 without the need for breaks, significantly boosting production.

Consistent quality

Robots perform tasks with high precision and repeatability, reducing errors and improving the quality of the final product.

Flexibility

Robotic systems can be programmed to handle various operations and types of machines, easily adapting to changes in production.

Reduced Operational Costs

Automation can lower labor costs while simultaneously increasing overall process efficiency.

Safety

Automating repetitive and potentially hazardous tasks reduces the risk of injuries to human workers.