Deburring

What is

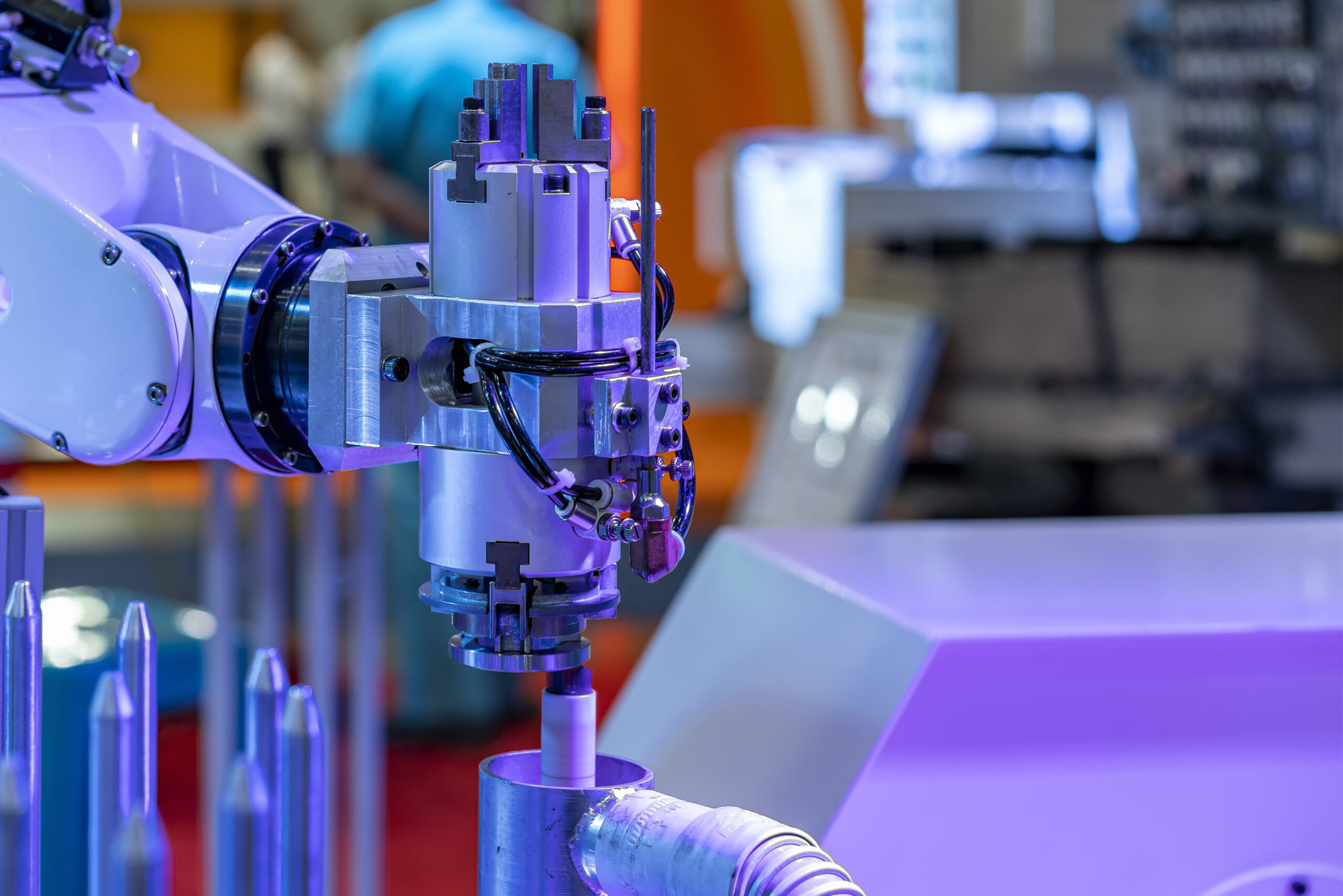

Robotic deburring is an industrial automation technique that uses robots to remove burrs and irregularities from machined parts. This process is crucial to ensure that finished components are defect-free and ready for assembly or final use. Deburring is especially important in industries such as automotive, aerospace, metalworking, and plastic manufacturing.

Common application

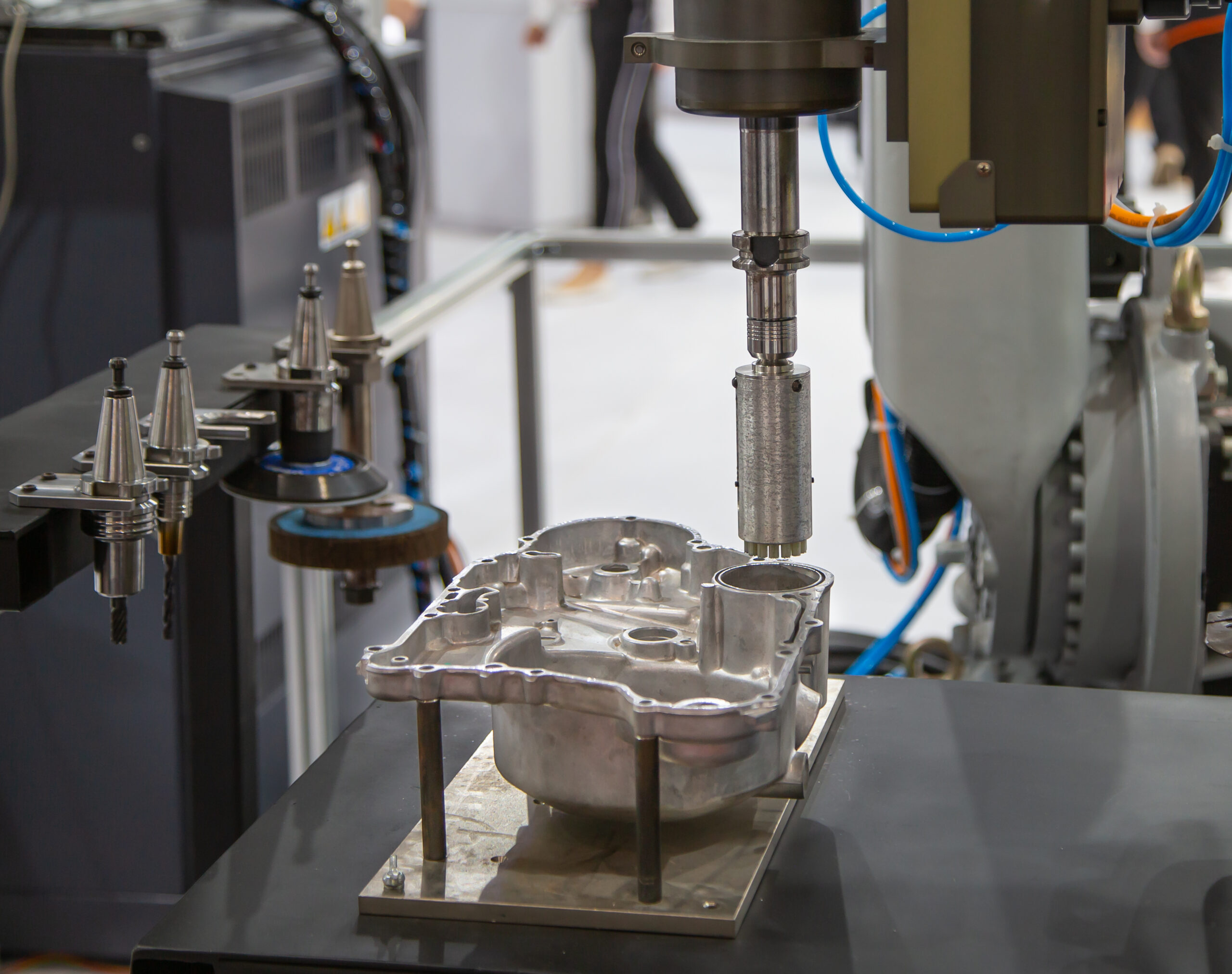

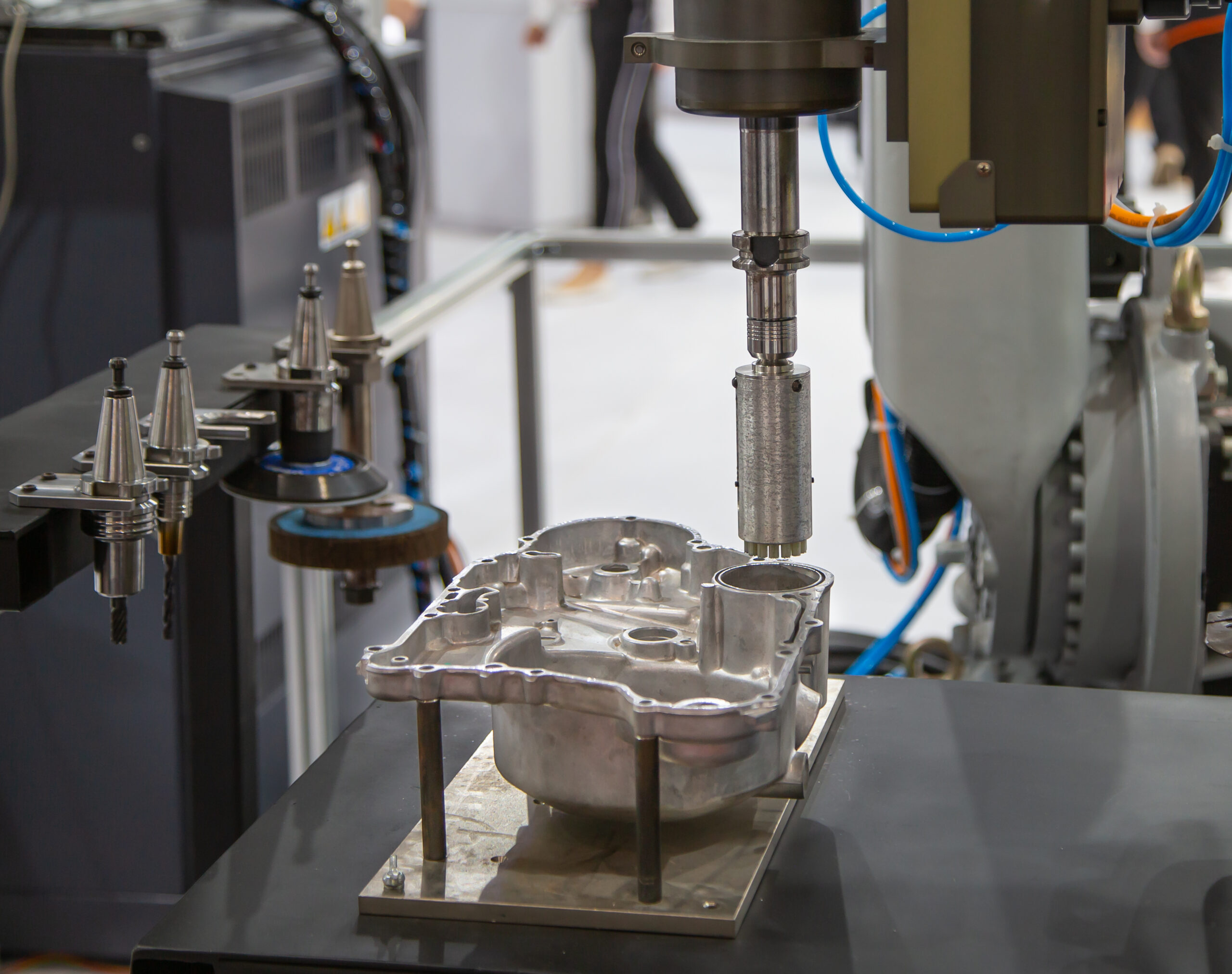

Metal Components

Deburring of turned, milled, or stamped parts such as gears, housings, and structural components.

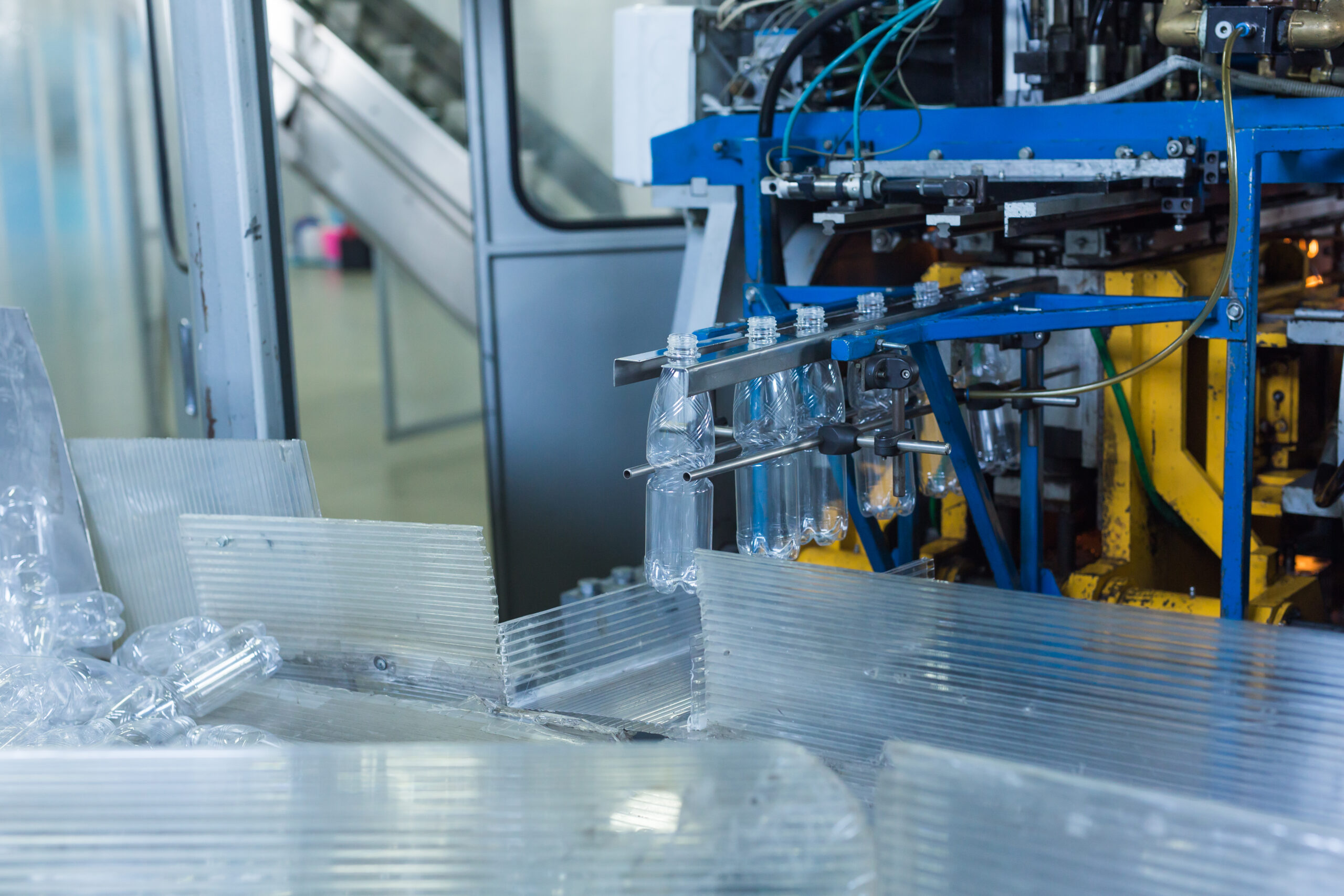

Plastic Components

Removal of burrs from injection-molded parts.

Composite Material

Deburring of carbon fiber parts or other composite materials.

Aerospace Industry

Deburring of critical components that require high precision and surface quality.

Advantage of Robotic Deburring

Increased Productivity

Robotic systems can operate continuously without interruptions, significantly boosting productivity compared to manual processes.

Consistent Quality

Robots ensure consistent and repeatable quality in burr removal, eliminating the variations that can arise from manual work.

Flexibility

Robots can be programmed to handle various types of parts and deburring processes, easily adapting to new products or changes in production requirements.

Reduced operational costs

Although the initial investment may be high, automation reduces long-term costs due to greater efficiency and fewer errors.

Safety

Robots perform potentially hazardous tasks, reducing the risk of injuries for human operators.