Packaging

What is

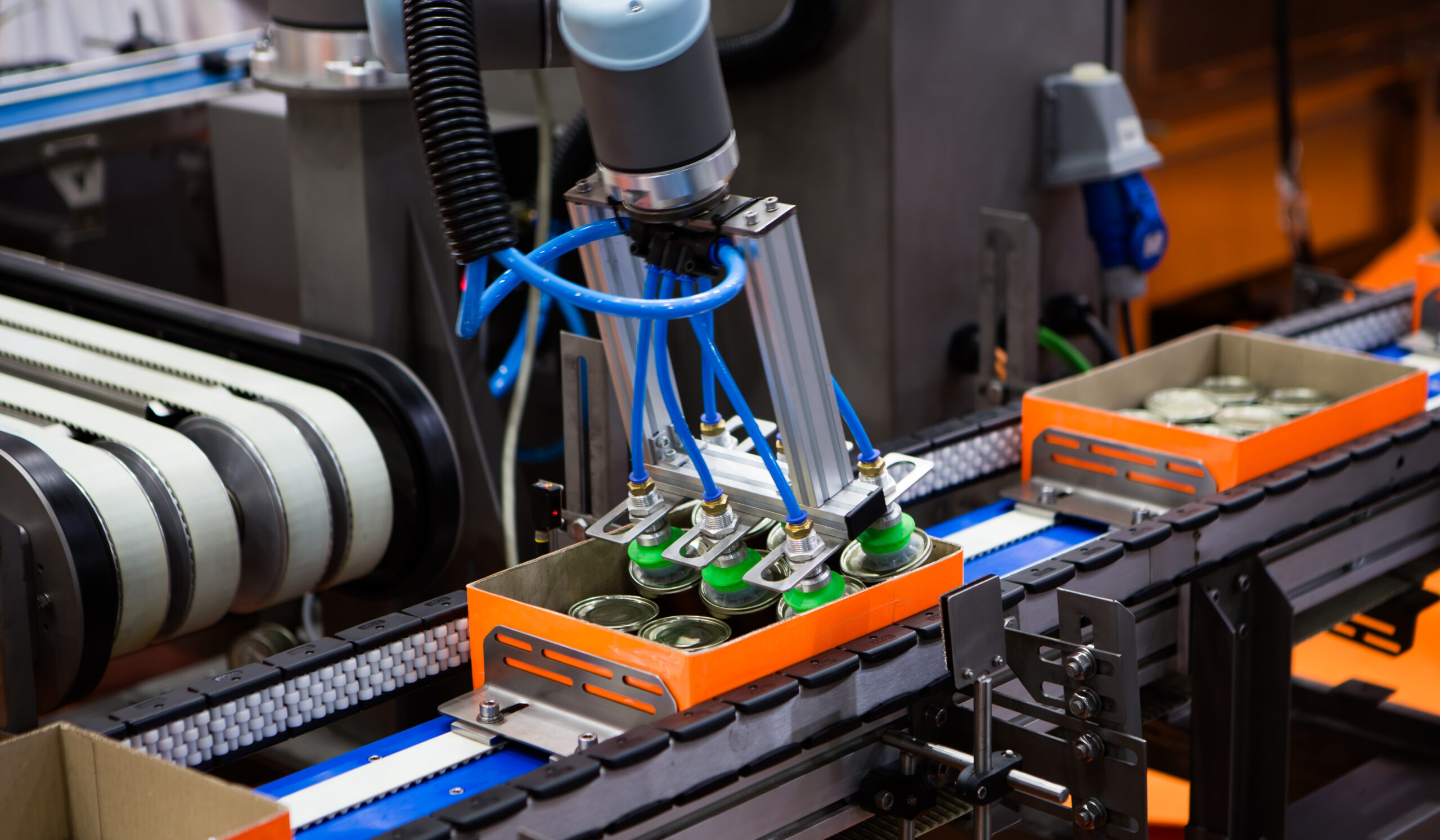

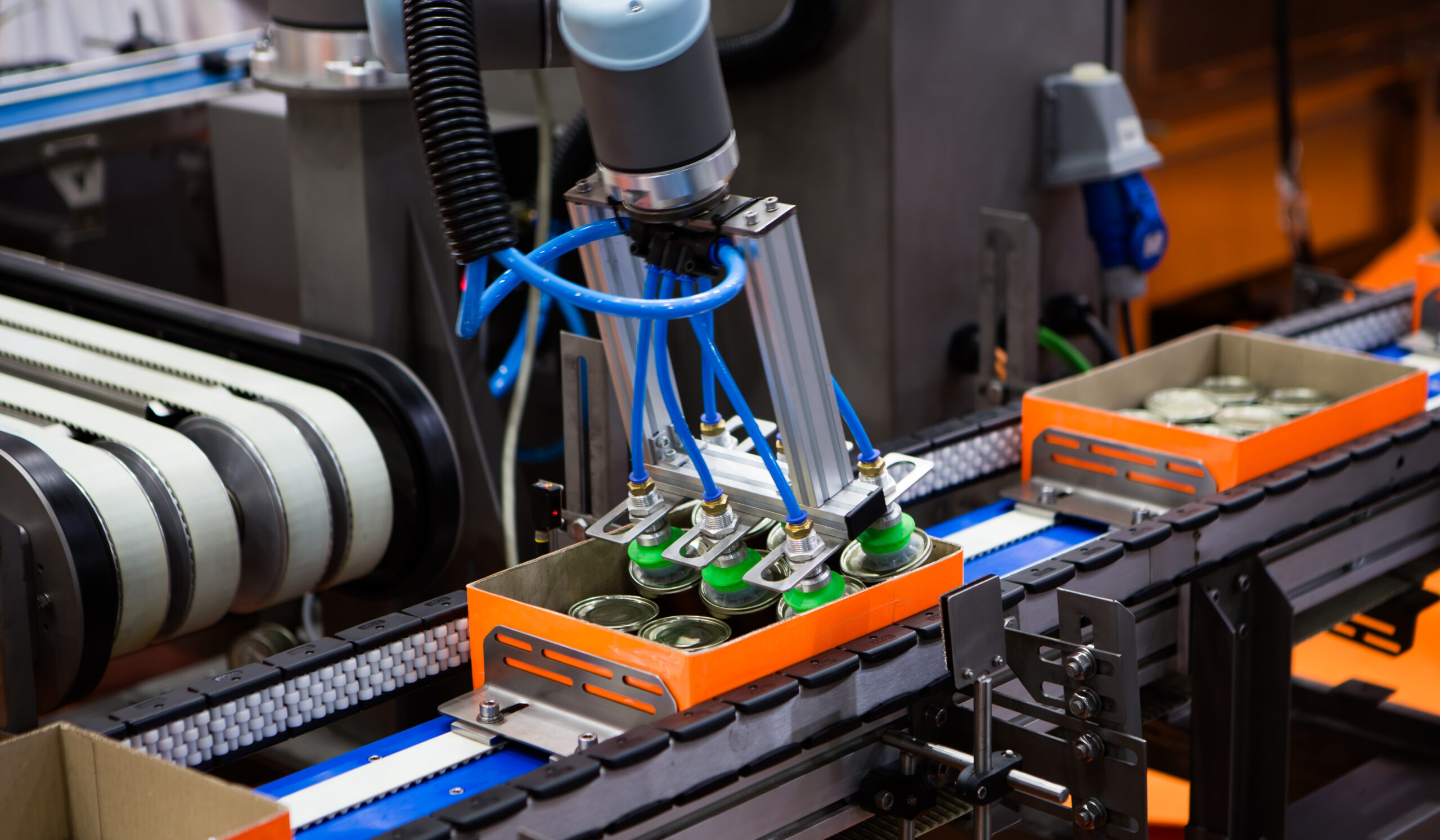

Robotic packaging refers to the automated process of preparing products for distribution and sale using robotic systems. This technology is extensively used in manufacturing and logistics industries to streamline packaging operations, improve efficiency, and enhance overall product handling capabilities.

Common application

Food and Beverage

Packaging of food products, beverages, and perishable items into containers, trays, and boxes.

Consumer Goods

Packaging of household products, personal care items, and electronics into retail-ready packages.

Pharmaceuticals

Sorting and packaging of medications, pills, and medical devices into blister packs, bottles, and cartons.

E-commerce Fulfillment

Sorting and packaging of orders for online retailers, including picking items from inventory and preparing them for shipment.

Advantages of Robotic Packaging

Speed and Efficiency

Robots can perform packaging tasks at high speeds, increasing throughput and reducing cycle times compared to manual methods.

Consistent Quality

Automated systems ensure uniformity in packaging quality, minimizing errors and variations that can occur with human operators.

Flexibility

Robots can handle a wide range of products and packaging formats, easily adapting to changes in production requirements.

Spece Optimization

Robots are capable of compact and precise movements, optimizing use of warehouse and production floor space.

Safety

Automation reduces reliance on manual labor for repetitive and physically demanding packaging tasks, thereby lowering labor costs.

Future of Robotic Packaging

As technology advances, the future of robotic packaging is expected to focus on:

Collaborative Robotics

Robots that work alongside human operators in shared workspaces, enhancing flexibility and safety.

Artificial Intelligence

AI-powered systems that optimize packaging processes, predict maintenance needs, and improve overall efficiency.

Modularity and Scalability

Modular robotic systems that can be easily scaled and reconfigured to accommodate changing production demands and packaging requirements.