Welding

What is

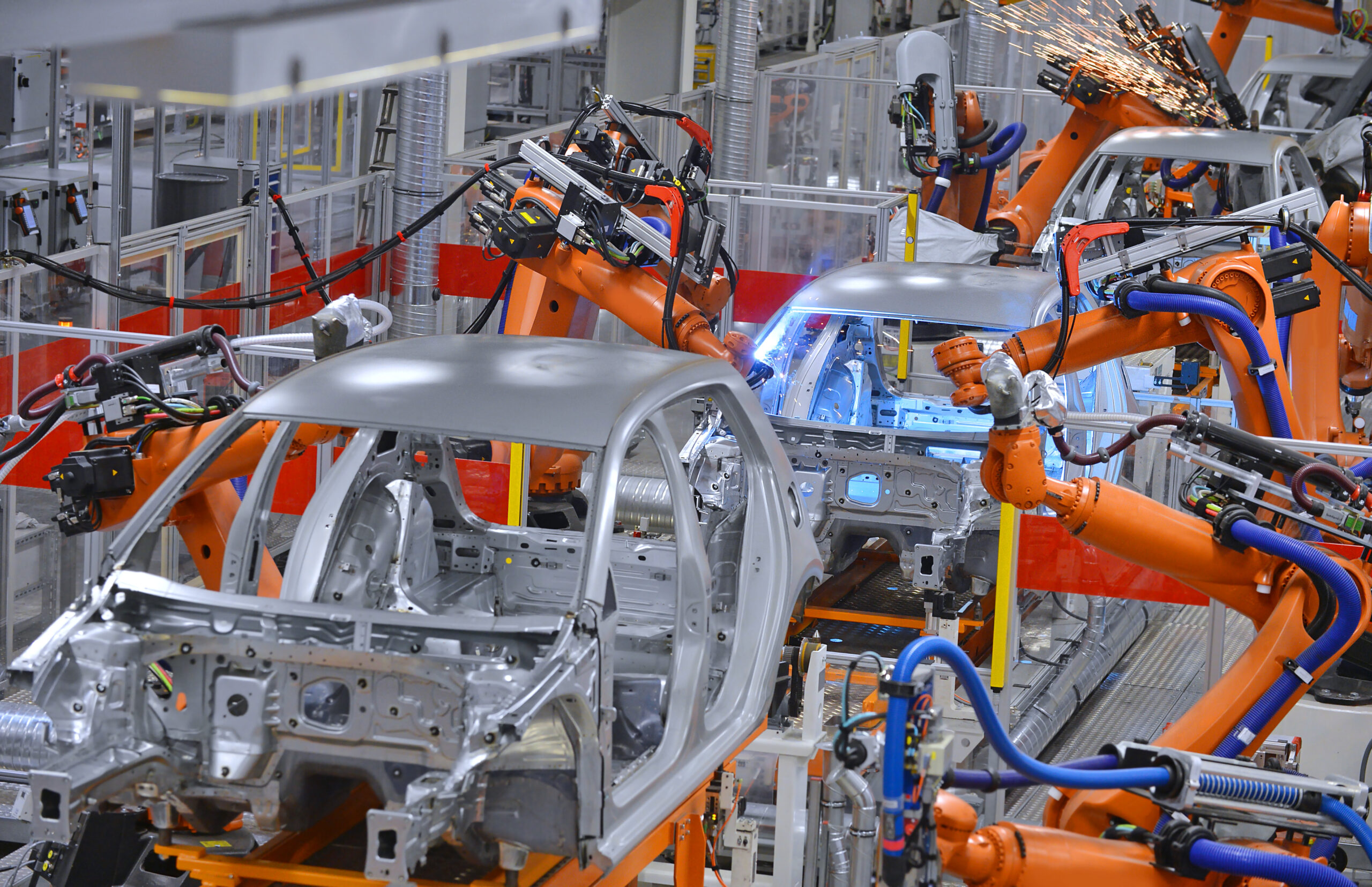

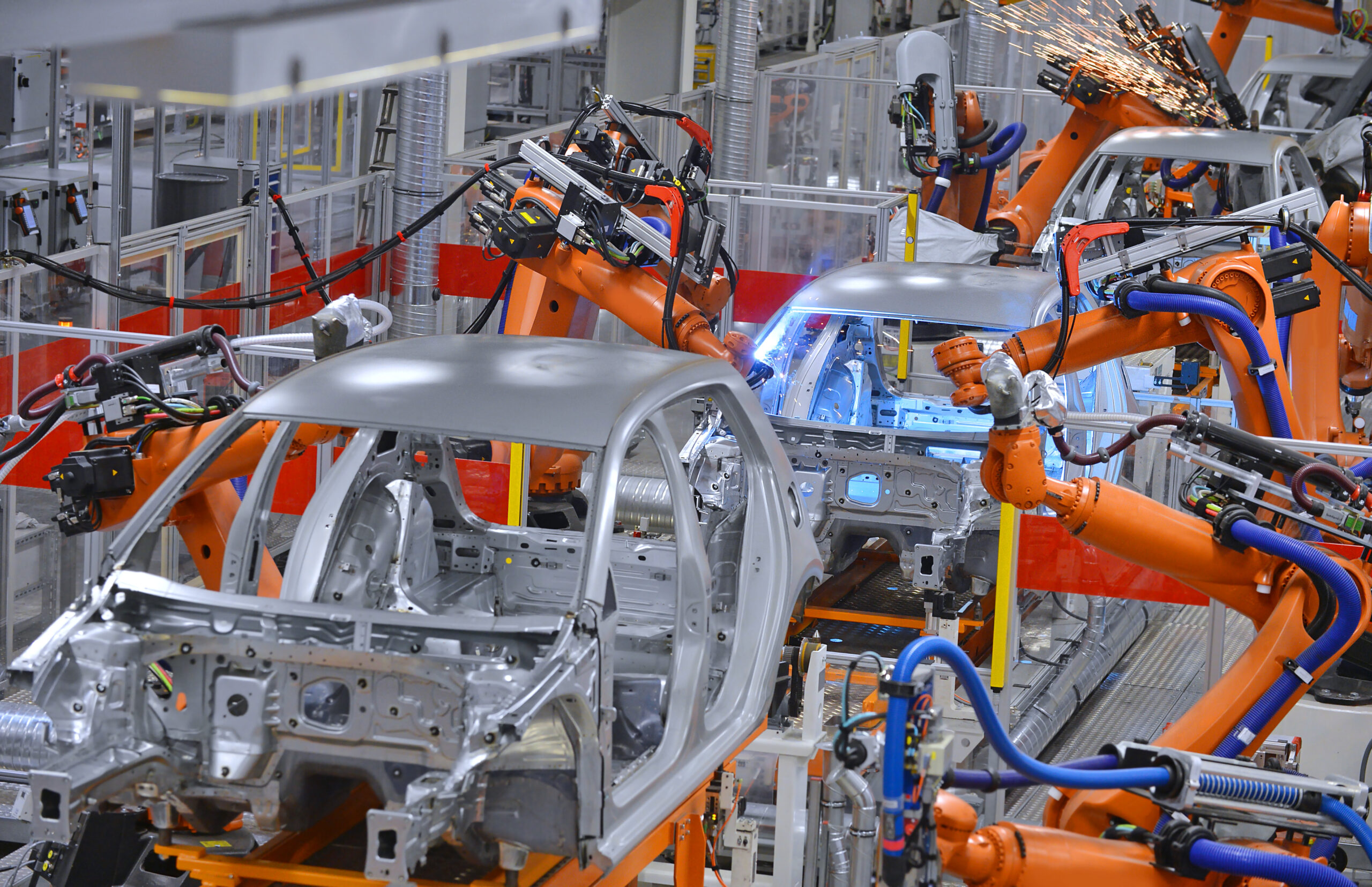

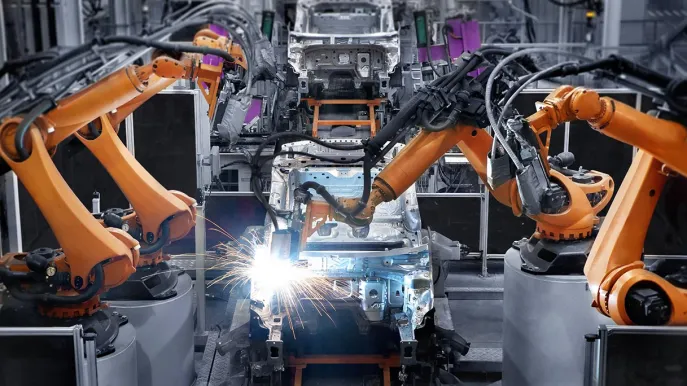

Robotic welding utilizes robots to perform welding operations in industrial settings. This technology is widely used in industries such as automotive, aerospace, heavy machinery manufacturing, and electronics due to its numerous benefits in terms of precision, efficiency, and safety.

Common application

Automotive Industry

Assembly of frames, bodies, and metal components.

Aerospace

Production of critical components requiring high-precision welds.

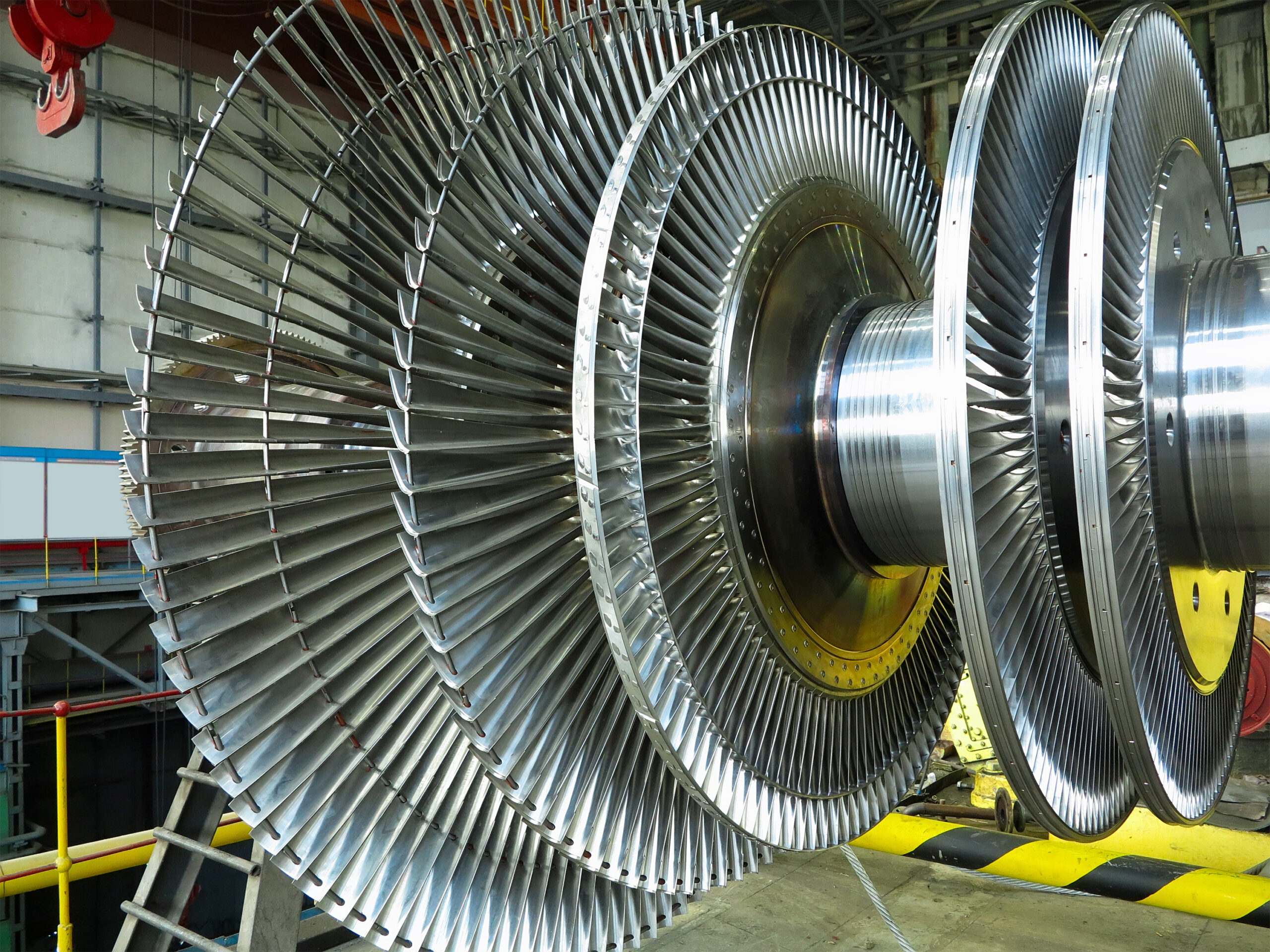

Heavy Machinery

Joining large components and complex structures.

Friction Welding

Uses heat generated by friction between a rotating tool and the workpiece to join materials.

Advantage of Robotic Welding

Increased Productivity

Robots can operate 24/7 without needing breaks, significantly boosting production capacity.

Precision and Repetability

Robots can perform welds with high precision and repeatability, reducing defects and improving the final product’s quality.

Flexibility

Robotic welding systems can be programmed to handle various welding types and workpiece configurations, easily adapting to production changes.

Consistent Quality

Robots provide uniform and consistent welds, eliminating variations due to fatigue or human error.

Safety

Welding can be hazardous, exposing operators to risks of burns, toxic fumes, and radiation. Using robots reduces workers’ exposure to these dangers.